3D scanning technology has emerged as a transformative tool across various industries, offering unique capabilities for measuring and digitizing physical objects. This report outlines the importance of 3D scanning, its functionalities, applications, and future potential.

Defining 3D Scanning

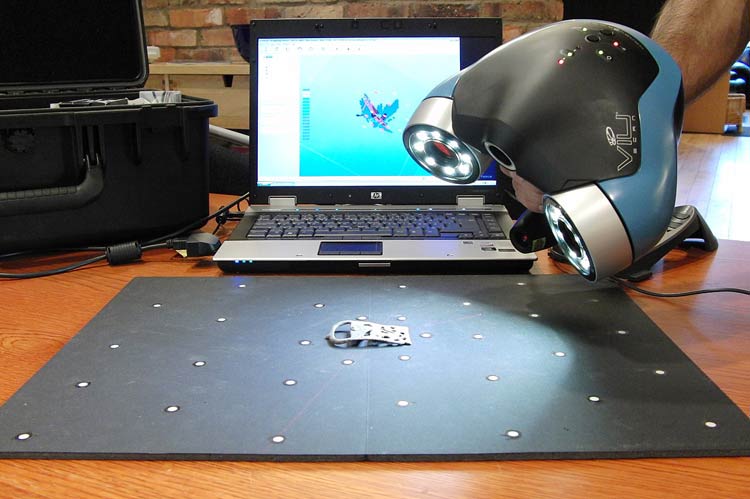

3D scanning involves capturing an object's shape and appearance to create digital 3D models. This technology utilizes sensors such as lasers or structured light to obtain precise measurements from the object, forming a 'point cloud' that represents its surface. Following this, the point cloud data is processed to create a mesh model, which can then be textured for realism. The entire process enhances the accuracy and efficiency of creating 3D representations of physical items and is essential for tasks requiring detailed geometric data[1][4].

Versatile Applications Across Industries

3D scanning has found applications in numerous fields, including entertainment, medicine, architecture, and engineering. In the movie and video game industries, 3D scanning allows artists to create lifelike characters and props efficiently compared to traditional modeling techniques[1][5]. It is similarly beneficial in the medical sector, where it aids in the design of prosthetics and implants, enhancing the fit and comfort for patients while accelerating production processes through 3D printing technologies[1].

In architecture, 3D scanning provides accurate measurements and visualizations of buildings, allowing architects to create detailed designs and perform reverse engineering to improve existing structures[1][2]. The technology also plays a crucial role in the construction and engineering sectors for site modeling and quality control, enabling iterative improvements in design and craftsmanship[2][5].

Technological Advancements and Integration

Modern advancements in technology have significantly enhanced the functionality and ease of use of 3D scanning equipment. Contemporary scanners can deliver high-quality data with minimal operator expertise, transforming 3D scanning from a specialized task into an integral part of the design and manufacturing workflow[2]. The integration of 3D scanning data into generative design processes helps engineers to optimize creations from the outset, ultimately improving the quality of the final parts while reducing rework and material waste[2].

Moreover, with the incorporation of artificial intelligence (AI), 3D scanning can facilitate real-time data analysis and decision-making, significantly augmenting manufacturing processes. AI systems can leverage intricate data provided by 3D scans to refine algorithms used in production, enhancing accuracy and efficiency[2][5].

Historical Context and Evolution

The journey of 3D scanning technology began in the late 1980s when the first imaging triangulation systems were installed for industrial applications. Early systems primarily focused on surface inspection and comparative measurements but required significant manual intervention. Over time, the technology has matured into a user-friendly solution capable of adapting to various industrial needs[3]. The rise of high-definition 3D scanners has revolutionized cultural heritage conservation, archaeology, and paleontology, enabling the detailed documentation of artifacts and structures without physical contact[3].

Challenges and Limitations

Despite its advantages, there are challenges associated with 3D scanning technology. Environmental factors, such as lighting conditions, can significantly impact the quality of scans. Additionally, there is a need for adequate training to utilize the technology effectively, which ensures accurate results[5]. While 3D scanning systems have become more portable and easier to use, they still face constraints regarding size, scanning time, and the costs associated with high-performance devices[5].

Looking Ahead

The future of 3D scanning appears promising as the technology continues to evolve. With projections indicating consistent growth in the market, more sectors are likely to realize the benefits of incorporating 3D scanning into their processes. The integration of advanced AI with 3D scanning systems holds the potential to enhance data accuracy further, facilitate better inspection processes, and ultimately streamline production workflows[4][5].

In conclusion, 3D scanning technology is not merely a tool for creating digital models; it is a catalyst for innovation across multiple industries. Its ability to provide precise measurements, facilitate rapid prototyping, and inform design decisions underscores its significance in today's technological landscape. As the technology advances, its applications will undoubtedly expand, offering even greater efficiency and accuracy in capturing the physical world.

Get more accurate answers with Super Pandi, upload files, personalized discovery feed, save searches and contribute to the PandiPedia.

Let's look at alternatives:

- Modify the query.

- Start a new thread.

- Remove sources (if manually added).