Introduction

This report provides a comprehensive analysis of the life-cycle greenhouse gas (GHG) emissions associated with electric and hydrogen trucking. It examines key stages including vehicle manufacturing, fuel production, operational fuel consumption, and infrastructure deployment, while also considering the sensitivity to regional energy mixes. The evaluation is based on studies carried out by the International Council on Clean Transportation (ICCT) along with insights into hydrogen fueling infrastructure challenges.

Vehicle Manufacturing and Material Extraction

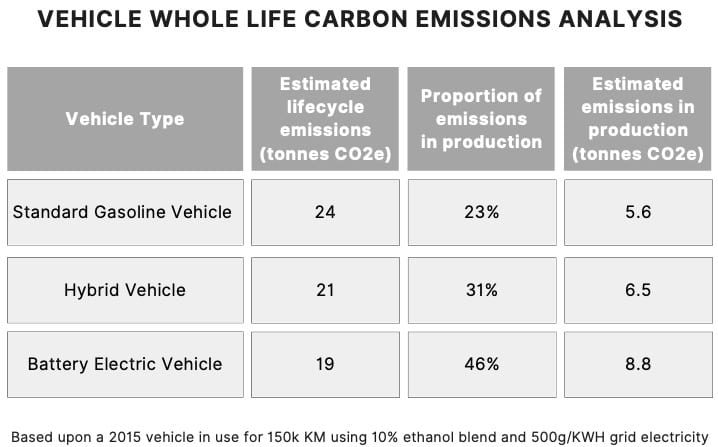

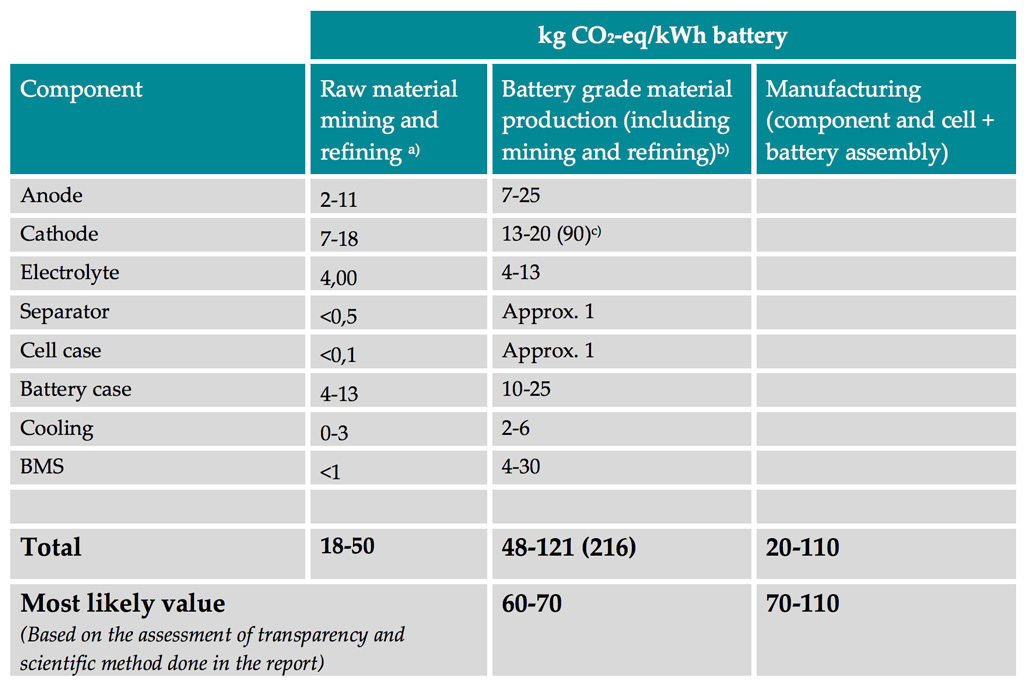

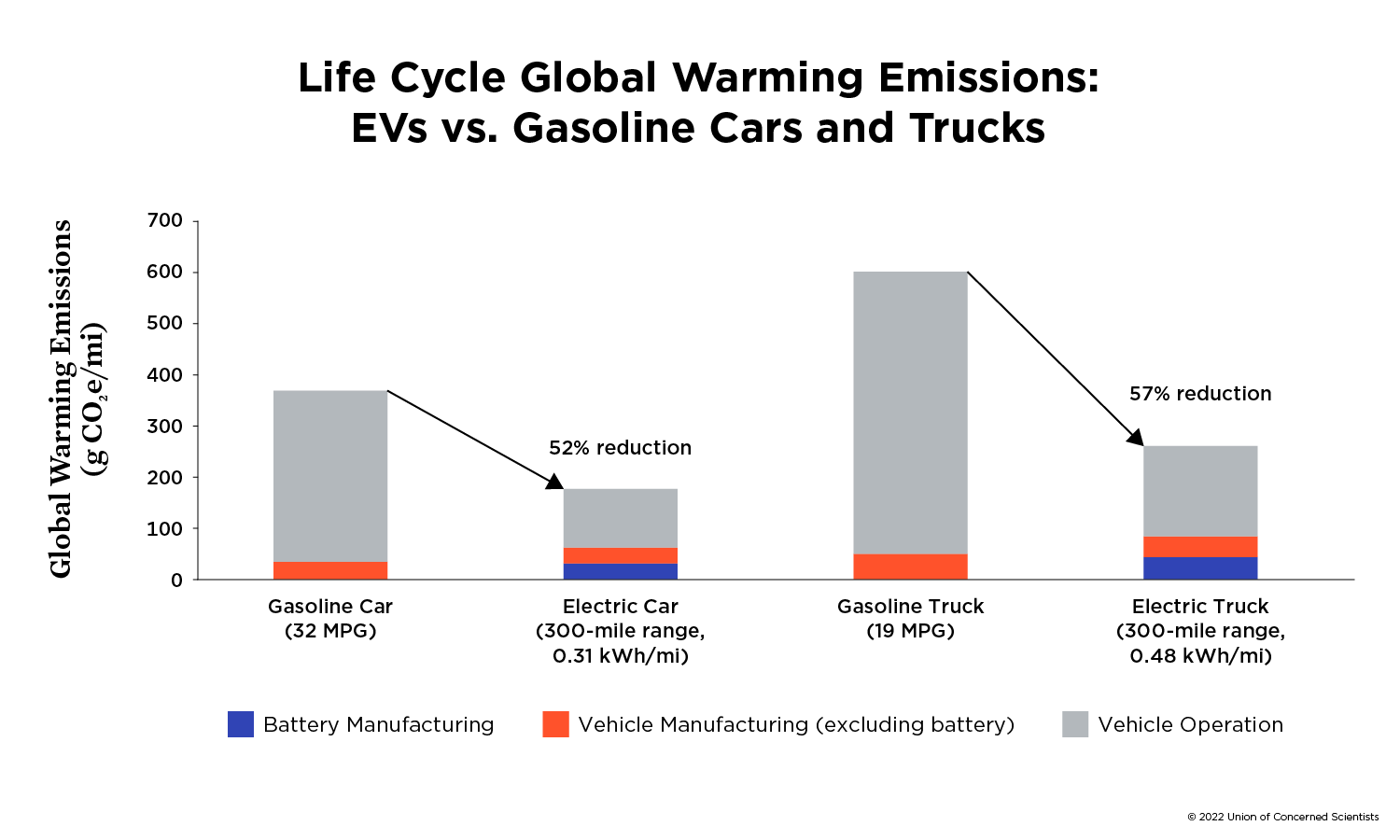

Both electric and hydrogen trucks require energy-intensive manufacturing processes; however, the ICCT analyses indicate that the emissions generated during manufacturing are generally a small portion of the total life-cycle emissions when compared to the fuel consumption phase. For instance, despite battery electric vehicles having relatively higher emissions during production—largely due to battery production—these are offset over the vehicle's lifetime by a significant reduction in fuel cycle emissions. This trend is consistent across multiple analyses where manufacturing emissions play a minor role relative to operational use[1][2].

Fuel Production and Energy Mix Sensitivity

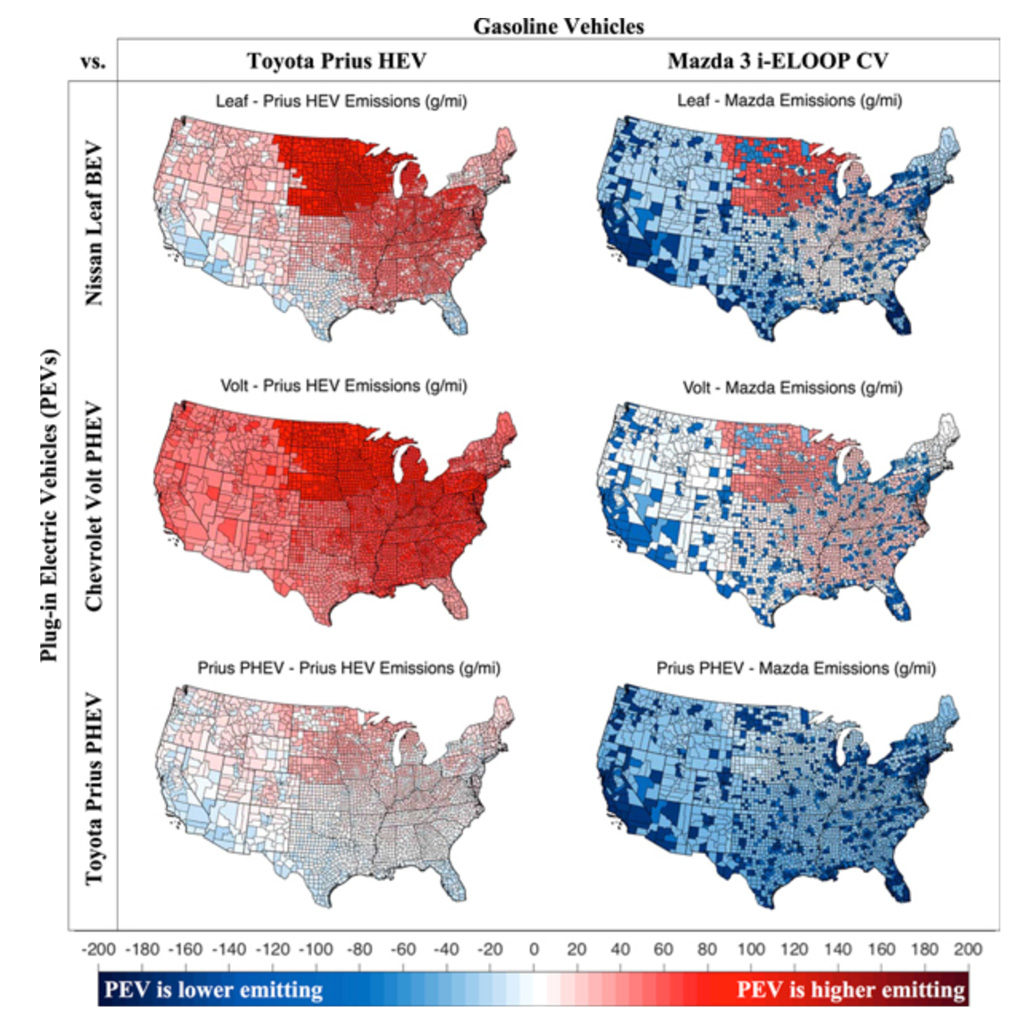

Fuel production constitutes a major contributor to the overall life-cycle emissions of heavy-duty vehicles. Battery electric trucks, for example, produce at least 63% lower lifetime GHG emissions than their diesel counterparts when using the European Union's current average electricity grid mix. Moreover, projections suggest that these reductions can soar to as high as 92% if 100% renewable electricity is used. In contrast, fuel cell electric trucks operating on hydrogen produced from fossil fuels only achieve emission reductions in the range of 15% to 33% compared to diesel; however, if the hydrogen is produced using renewable electricity, the emissions can fall by up to 89%[1][2].

These findings underscore the crucial role of the regional energy mix. Sensitivity analyses reveal that the environmental benefits of battery electric trucks are highly dependent on how clean the electricity grid becomes over the vehicle's lifetime, making policy and investment in renewable energy vital to further decarbonization.

Operational Phase and Fuel Consumption

The operational or use phase dominates the total life-cycle GHG emissions for heavy-duty trucks. For conventional diesel and natural gas trucks, over 90% of the emissions arise from fuel consumption. In contrast, the high energy efficiency of battery electric powertrains greatly reduces emissions during operations, effectively compensating for the higher carbon footprint generated during vehicle and battery production. The efficiency advantage is a critical factor that ensures battery electric trucks remain the most attractive option for reducing greenhouse gas emissions over their lifetime[1].

Infrastructure Considerations

In addition to the vehicle-specific attributes, the availability and deployment of fueling infrastructure profoundly impact the practicality and environmental performance of the different powertrain options. Battery electric trucks benefit from an expanding network of EV charging infrastructure, which, though still evolving, is supported by ongoing improvements in grid decarbonization. Conversely, hydrogen trucks face significant hurdles related to refueling infrastructure. The development of hydrogen fueling stations is currently uneven, with regions like California and countries across parts of Europe taking early steps, but overall, the infrastructure for hydrogen remains sparse. For example, in the UK, while hydrogen refueling stations have been trialed, a limited network has hindered widespread adoption, underscoring the need for substantial public and private investment to support hydrogen as a viable long-haul transport solution[6].

End-of-Life and Lifecycle Integration

Although detailed discussions on end-of-life processes are not extensively covered in the sources, the overall life-cycle approach integrates vehicle manufacturing, fuel production, and the maintenance phases with the eventual decommissioning and recycling of materials. The studies stress that while there are emissions associated with vehicle end-of-life handling, these factors are minor compared to the cumulative emissions from fuel production and operational use. An integrated evaluation of the entire life cycle—encompassing manufacturing, operation, and end-of-life management—confirms that the operational phase is the most critical component in determining the environmental performance of trucking technologies[1][2].

Conclusion

The life-cycle assessment clearly shows that battery electric trucks offer the greatest potential for reducing greenhouse gas emissions compared to traditional diesel and natural gas trucks, primarily due to their high operational efficiency and the expanding potential for clean electricity. However, the benefits are closely tied to the regional energy mix, highlighting the importance of transitioning to renewable energy sources. Hydrogen trucks, while offering a promising route—especially when using hydrogen produced from renewable sources—currently lag behind in terms of both emission reductions and supporting infrastructure. Also, a comprehensive analysis that includes manufacturing and end-of-life phases reinforces that while production emissions are important, the dominant factor in environmental performance remains the fuel consumption during the operational life of the vehicles. To fully unlock the potential of both technologies, efforts must continue in decarbonizing energy grids and expanding infrastructure networks, ensuring that the entire life cycle of these vehicles is as low-carbon as possible.

Get more accurate answers with Super Pandi, upload files, personalized discovery feed, save searches and contribute to the PandiPedia.

Let's look at alternatives:

- Modify the query.

- Start a new thread.

- Remove sources (if manually added).